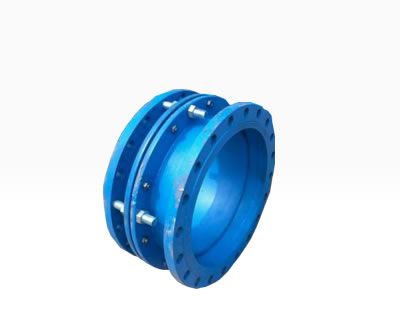

Introduction to SSQ-2 Tubular Telescopic Device

Casing type expansion joint is also called expansion joint, expansion joint and compensator. The sleeve type telescopic device can be axially retracted within a certain range, and can also overcome the deviation caused by the different axial directions of the pipe butt joint within a certain angle. It can greatly facilitate the installation and disassembly of the valve pipe. It can be freely retracted within the allowable expansion amount of the pipe, and once it exceeds its expansion amount, it plays a limiting role to ensure the smooth operation of the pipe.

Detailed Description of SSQ-2 Tubular Telescopic Device

1. Sleeve type expansion device This product provides great convenience for the installation and replacement of various water supply and drainage pipelines, water towers, pumps, water meters, and valves, and plays a good regulatory role in the expansion and contraction of long-distance pipelines due to temperature differences.

2. {Full Name of the Enterprise} - The manufacturer's innovative pipe production sleeve type expansion joint. The internal pipes of this product are divided into three types: cast iron (HT), galvanized (DX), and steel (SF). The working pressure is divided into PN6, PN10, and PN16.

3. Before installing the sleeve type telescopic device, loosen the pressure plate bolts, pull the product to the installation length, and then tighten it using the diagonal method. Do not press it sideways. If it is used overhead, install corresponding fixing brackets at both ends.

4. The flange connection of the sleeve type expansion joint adopts GB4216.3-4126.5 standard.

5. If other specifications are selected, they can be produced separately.

Connection Instructions for SSQ-2 Tubular Telescopic Device

There are two types of flange connection and welding, and welding is generally used for directly buried expansion joints (non trench and well installation).

Precautions for Installation of SSQ-2 Tubular Telescopic Device

1. Before installing a sleeve type expansion joint, its model, specification, and pipeline configuration should be checked to ensure that they meet the design requirements.

2. For telescopes with inner sleeves, attention should be paid to making the direction of the inner sleeve consistent with the direction of media flow, and the hinge rotation plane of hinge type telescopes should be consistent with the displacement rotation plane.

3. For telescopes that require "cold tightening", the auxiliary components used for pre deformation of sleeve type telescopes should not be removed until the pipeline is installed.

4. It is strictly prohibited to use the method of deformation of the expansion joint to adjust the installation tolerance of the pipeline, in order to avoid affecting the normal function of the expansion joint, reducing its service life, and increasing the load on the pipe system, equipment, and supporting components.

5. During the installation of sleeve type telescopes, it is not allowed to splash welding slag onto the surface of the wave casing, and it is not allowed to suffer other mechanical damage to the wave casing.

6. After the installation of the telescopic tube system, the yellow auxiliary positioning components and fasteners used for installation and transportation on the telescopic tube should be removed as soon as possible, and the limit device should be adjusted to the specified position according to the design requirements, so that the tube system has sufficient compensation capacity under environmental conditions.

7. All moving components of the sleeve type telescopic device shall not be blocked or restricted by external components, and the normal operation of each moving part shall be ensured.

8. During the hydrostatic test, the secondary fixed pipe rack at the end of the pipeline equipped with a telescopic sleeve should be reinforced to prevent the pipeline from moving or rotating. For expansion joints and their connecting pipes used for gaseous media, it is important to note whether temporary supports need to be added during water filling. The 96 chloride ion content of the water cleaning solution used for hydrostatic testing shall not exceed 25 PPM.

Technical Parameters of SSQ-2 Tubular Telescopic Device

|

Nominal diameter |

Minimum length |

Installation length |

Maximum length |

Expansion and contraction amount |

|

40 |

130 |

150 |

170 |

40 |

|

50 |

135 |

155 |

175 |

40 |

|

65 |

150 |

175 |

200 |

50 |

|

80 |

170 |

200 |

230 |

60 |

|

100 |

170 |

205 |

240 |

70 |

|

125 |

190 |

225 |

260 |

70 |

|

150 |

210 |

250 |

290 |

80 |

|

200 |

220 |

260 |

300 |

80 |

|

250 |

235 |

275 |

315 |

90 |

|

300 |

235 |

280 |

325 |

90 |

|

350 |

250 |

295 |

340 |

90 |

|

400 |

260 |

305 |

350 |

90 |

|

450 |

260 |

305 |

350 |

90 |

|

500 |

270 |

315 |

360 |

100 |

|

600 |

280 |

330 |

380 |

100 |

|

700 |

300 |

350 |

400 |

100 |

|

800 |

330 |

380 |

430 |

100 |

|

900 |

330 |

380 |

430 |

100 |

|

1000 |

350 |

400 |

430 |

100 |

|

1200 |

350 |

400 |

450 |

100 |

|

1400 |

390 |

445 |

450 |

110 |

|

1600 |

410 |

465 |

500 |

110 |

|

1800 |

430 |

485 |

520 |

110 |

|

2000 |

450 |

510 |

540 |

120 |

|

2200 |

480 |

545 |

570 |

130 |

|

2400 |

500 |

570 |

610 |

140 |

|

2600 |

540 |

615 |

640 |

150 |

|

2800 |

580 |

660 |

690 |

160 |

|

3000 |

650 |

750 |

740 |

200 |

! Zhongyuan people sincerely wish customers May our joint efforts lead to unprecedented success and growth in the global market.! Zhongyuan Water Supply and Drainage Equipment is looking forward to cooperating with you. It is a great honor for Zhongyuan to provide you with SSQ-2 casing type telescopic device series products of continuous innovation!